Location:

30-50 Mill Street, Arlington, Massachusetts 02476

Just 20 minutes northwest of Boston, MA, Arlington is a historically rich town founded over 350 years ago. The building site for the apartment complex was previously the headquarters of Brigham’s Ice Cream from 1968-2008.

The Building:

The Mill Street Apartments includes 116 apartment units as well as a small office/retail building. The complex was designed by CUBE 3 Studio, LLC. in Lawrence, Massachusetts. www.cube3studio.com ?The Developer was Wood Partners. www.woodpartners.com?The General Contractor was Callahan, Inc. www.callahan-inc.com

Progressive Foam Insulation:

HalfbackH20 Universal Siding Insulation was specified by Cube 3 Studio, LLC to be installed underneath the exterior fiber cement lap and panel siding. HalfbackH20 provided R-4.2 insulation on the exterior as well as maximum moisture management with drainage grooves built into the foam and a permeability rating of 2.5. The project is estimated to require over 1,000 squares of HalfbackH20 before completion.

Why HalfbackH2O Was Used:

Arlington, MA is one of many cities in MA that has adopted the state’s Stretch Energy Code, requiring 20% improvement in energy efficiency of new buildings. The Stretch Code, much like the 2012 International Building Code and Energy Star for Homes Version 3, encourages the use of exterior insulation.

Although it is estimated that the code raises the cost of commercial construction from 1-3%, case studies have shown pay backs of 1-2 years, when standard incentives from electric companies are included on the benefits side.

?The drainage grooves (of HalfbackH20) are critical to the performance of the wall?, says Project Manager Aaron Bancroft, AIA LEED AP of CUBE 3 Studio, LLC. ?Without the drainage grooves, constant moisture up against the water resistive barrier could work its way into the wall.?

In our last milestone post about important events throughout Progressive Foam’s 20+ year history, we took a look back at how the company got its start in 1992. For this post we will flash forward to 1995, the year that Progressive Foam found a home in Beach City, Ohio.

In our last milestone post about important events throughout Progressive Foam’s 20+ year history, we took a look back at how the company got its start in 1992. For this post we will flash forward to 1995, the year that Progressive Foam found a home in Beach City, Ohio.

Prior to 1995, founder Pat Culpepper and a handful of employees were working out a small pole building just south of New Philadelphia, Ohio, making siding insulation for use behind vinyl siding. On December 2nd, 1995, the company moved into the Beach City facility, which at the time was only 36,000 square feet. Culpepper recalls thinking ?What have we done, we’ll never fill all of this space!?

By 2006, Progressive Foam had indeed outgrown the space. The first addition was made to the facility, providing 40,000 additional square feet of operating space. In that same year, Progressive Foam built the first commercial-size machine for laminating siding insulation to vinyl siding. Building the machine took a leap of faith, as Culpepper did not have a single customer committed to buying a laminated insulated vinyl siding at the time.

When the lamination machine first launched, the goal was to have the capability to laminate 200 squares (or 20,000 square feet) of insulated vinyl siding in one day.? Originally Culpepper was told that the goal was impossible. To put that in perspective, today we are now able to laminate 200 squares in just three hours.

In our next milestone post we will cover the official commercial launch of insulated vinyl siding in the marketplace.

What is Neopor?

IN 2013 at the International Builders' Show in Las Vegas, Progressive Foam released a new "Premium Series" of siding insulation products made of Neopor by BASF, the world's largest chemical company. Whether you're familiar with Neopor or this is the first time you're hearing about it, there are some interesting details about this insulation material that you may not be aware of:

First, What is Neopor?

Neopor is a material patented and manufactured by BASF. Composed of small grey beads of polystyrene granules containing a blowing agent, which makes it expandable, these beads are manufactured into insulation products by BASF's customers, like Progressive Foam.

What Makes Neopor Different?

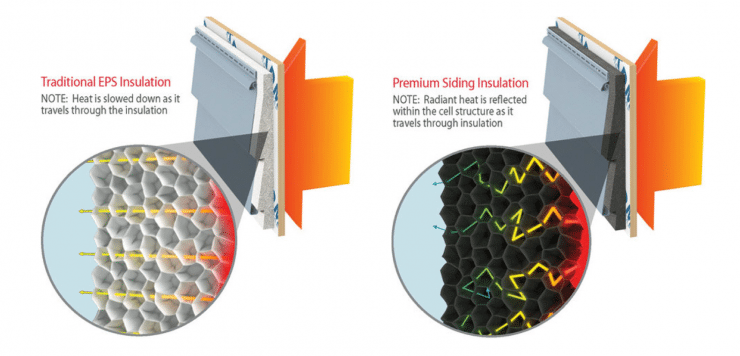

Neopor works in the very same way as traditional insulation, with one major difference -- high-purity graphite particles infused into the cell structure give Neopor a reflective property and a distinctive dark gray color.

As radiant heat moves through Neopor insulation, it reflects it hundreds of times, significantly slowing down the transfer of heat and making it more energy efficient!

Think of the heat transfer as a person walking on a path from point A to point B. Walking in a straight line (like traditional insulation) would be much faster than if the path took many twists and turns along the way (like Neopor). Read more on how Neopor compares to other types of insulation.

What is the History of Neopor?

BASF invented and patented EPS technology in 1950, forever changing the insulation landscape. Today’s game changer is Neopor. Although Neopor is relatively new to the United States, it has been used extensively in the Europe since BASF patented the material in 1995. Neopor is used in many different insulation applications, including EIFS, SIPS panels, and now, siding insulation by Progressive Foam.

What Products Are in Our Premium Series?

We are pleased to say that all of the siding insulation products we offer in traditional white EPS are now also available in Neopor! In addition, we also offer a fanfold product in Neopor, listed below.

FullbackV Premium- Siding Insulation for Vinyl

FullbackFC Premium- Siding Insulation for Fiber Cement

Linebacker Premium- Siding Insulation for use with fiber cement & composite wood

HalfbackH20 Premium Universal siding Insulation

ProFold Premium Universal Siding Insulation

Click here to learn more about Neopor!

Other Related Topics

New Siding Insulation with Built-In Moisture Management Adds R-3.8 Behind Brick and

Fiber Cement Siding?on University Residence Hall Complex

Location:

Located less than an hour outside of Harrisburg, Shippensburg?University is a bachelor and masters degree granting institute?with a rich history in teaching excellence.

The Project:

The three-building residence hall complex is four to five stories high, will?accomodate 924 university students and will cost an estimated $70 million when complete. The 306,436 square foot complex is just phase one?of a three-part project. All three phases are set for completion in the summer of 2015 and will cost a total of $200 million.

The complex was designed by CUBE 3 Studio, LLC. www.cube3studio.com

The general contractor was Fortune Johnson. www.fortune-johnson.com

The consulting engineer was Greenman-Pederson, Inc. ?www.gpinet.com

Campus Apartments is overseeing the project. www.campusapts.com

Progressive Foam Insulation

HalfbackH20 Universal Siding Insulation was specified by CUBE 3 Studio,?LLC to be installed underneath the exterior brick and fiber cement panel?siding. HalfbackH20 provided R-3.8 insulation on the exterior as well as?maximum moisture management with drainage grooves built into the foam?and a permeability rating of 3.5. The project is estimated to require over?1,500 squares of HalfbackH20 before completion.

Why HalfbackH20 Was Used

The University and CUBE 3 Studio, LLC were working hard to design these buildings to achieve Certified status under?the US Green Building Council’s LEED New Construction program.

In order to achieve this LEED Certified status on?this project, it was important that insulation be installed on the exterior of the building, and that the insulation be purchased from a manufacturer who was located no more than 500 miles from the construction site (saving on fuel used).

?Progressive Foam was able to work with us to provide a product that was versatile in meeting the performance goals?and construction techniques of the project,? says Project Manager John Harding, AIA LEED AP of CUBE 3 Studio,?LLC. ?They were able to deliver a cost-effective solution that was a great fit for the project.?

<Click here to download this case study in PDF format>

Happy New Year to all of the friends of Progressive Foam and readers of our blog. We hope you had a happy and prosperous 2012, and that 2013 brings even more health, wealth and happiness.

In 2012, Progressive Foam celebrated its 20 year anniversary. As a tribute to the history of the company, once a month during 2013 we will take a look back at the important milestones of the last 20 years. We will show how our company grew from its beginnings in a pole barn with one employee?into what it is today, an organization with over $22 million in sales annual that employs over 110 people.

There have been ups and downs along the way, as can be expected with any company that has been around for awhile, but Progressive Foam has continued to grow a rich history of product development and innovation, sustainable business practices and social responsibility.

As we reminisce on our history and continue looking forward to the future, please feel free to share any experiences you have had with Progressive Foam over the last 20 years!

___________________________________________________________

April 11, 1992 – The Beginning of Progressive Foam

Pat Culpepper, Co-founder & President

Progressive Foam’s co-founder and President, Patrick Culpepper, got his start in the foam business early in life at his father’s Michigan-based company in the 1970’s and 80’s. The business produced just about anything you could think of that could be made from foam. Culpepper learned the ins and outs of foam manufacturing during this time, from fixing machinery to selling finished products and more.

After his father’s company filed for bankruptcy in 1992, Culpepper took the lessons learned from his time at his father’s company and decided to forge a new path in the foam insulation business. With the idea for a new, innovative product in hand (which would later be called insulated vinyl siding) Culpepper borrowed $200,000 from two friends and founded Progressive Foam Technologies, Inc.

Progressive Foam aimed to remain committed to making high-quality insulation products with a commitment to product development, innovation and marketing.?The first facility was a small pole building located just south of New Philadelphia, Ohio, where they manufactured insulation for use behind vinyl siding.

“From the beginning, we envisioned that Progressive Foam would become a company that was focused on new product and new market development” says Culpepper, looking back on the start of the company. “It seemed a little hard to believe for most people when we were working out of a pole barn with a Porta-John.”

Springing from those humble beginnings, Progressive Foam has grown to operate out of a 111,000-square-foot facility outside of Beach City and make over $22 million per year in sales. Join us throughout the year as we continue to look back on milestones from the last 20 years.

As the year draws to a close and the holidays are upon us, we want to take a minute to thank all of the people that support Progressive Foam throughout the year, from our readers to our employees, from our customers to our vendors. It takes everyone involved to make a company and product successful, and we thank each of you for your continued support.

As the year draws to a close and the holidays are upon us, we want to take a minute to thank all of the people that support Progressive Foam throughout the year, from our readers to our employees, from our customers to our vendors. It takes everyone involved to make a company and product successful, and we thank each of you for your continued support.

As one of our customers, Don Cole Jr. of Autumn Exteriors, says in the video below, we have been faced with “challenging times” in the building products industry during the last few years. While some businesses have decided to scale back, make cuts and sell lower-quality products, Progressive Foam and our customers choose to continue supplying products that provide superior value for homeowners.

In addition, many indicators are telling us that 2013 should be a year of healthy growth in the remodeling industry, which could provide even more opportunities to grow businesses and give more homeowners the insulation solutions they need. We look forward to another great year of working together. Happy Holidays!

Click the video below for some inspirational words from Don Cole, Jr.

With the public more aware of how their lifestyles and decisions effect the environment than ever before, it is becoming more popular to choose products that have lower impacts than others. Some elements that affect a product’s environmental impact are the raw materials it’s made from, what it’s used for, and how it is disposed of when they’re no longer useful.

With the public more aware of how their lifestyles and decisions effect the environment than ever before, it is becoming more popular to choose products that have lower impacts than others. Some elements that affect a product’s environmental impact are the raw materials it’s made from, what it’s used for, and how it is disposed of when they’re no longer useful.

Products that can be recycled rather than thrown in the landfill after their life are significantly better for the environment than others. Siding insulation, made of expanded polystyrene (EPS), is one such product. Manufactured from 98% air and only 2% plastic, siding insulation reduces energy consumption, saving natural resources during its 40+ year life cycle. And when it’s time to remove the siding insulation, it can be recycled.

Reclaimed siding insulation?foam can be ground up and re-used in other applications, making other efficient building materials due to the recycled content. This is called post-consumer recycling, or recycling after the product has reached the end user. The only limitation is that siding insulation is only recyclable in select communities that have appropriate recycling facilities established. Many siding and insulation manufacturers are currently working to establish systems that make it easier to reclaim their products after they have been used.

Siding insulation can also go through pre-consumer recycling before it ever makes it to the marketplace. For instance, when manufacturing siding insulation, there is scrap material generated during the process. Rather than dispose of this material, it can be reclaimed and used in other products as well. Progressive Foam recently made a $400,000 investment in new equipment that consume 100% of the scrap from our manufacturing operations for use in other products. We are now working towards becoming a local recycling center for post-industrial and post-consumer foam waste.

For more information about how siding insulation impacts the environment, check out this Life Cycle Analysis report for insulated vinyl siding. More>

You may be wondering how new siding can look even more beautiful simply by adding insulation behind it during installation. After all, isn’t insulation used to improve energy-efficiency, not enhance appearance? Luckily, insulation is no longer known just for its energy saving properties.

Sure, insulation still helps to keep heat where it belongs (inside in the winter and outside in the summer) to help lower your utility bills and make your home more comfortable, but it does so much more than that. Some features of insulation products can actually make your siding look better. When you make the investment to put new siding on your home, don’t you want it to look as good as it possibly can?

Here are four ways that siding insulation can help to make your new siding job look even better, depending on which insulation product you choose:

1.) Levels the Wall

Every home has inconsistencies in its exterior wall surfaces, whether from the house shifting and settling over time or aging building materials. When new siding is installed, it can sometimes follow these inconsistencies in the wall, causing your brand new siding to look wavy and uneven.

Thick foam insulation panels help to level out the wall, providing a consistent, stable base for siding insulation and creating a beautiful, straight appearance.

2.) Provides Installation Guidelines

Some siding insulation products, such as HalfbackH20, also feature special installation lines on the face of the panel. This allows the siding installers to easily align with the studs when nailing new siding, promoting accurate installation for the best appearance and durability possible.

3.) Features Built-In Installation Ridges

(for plank-style sidings)

Plank-style siding products like fiber cement and composite wood can be difficult to install, requiring frequent measuring, chalk lines and guesswork. Even the best installers can sometimes make mistakes, causing your new siding to not be perfect like you expect.

Some siding insulation products, such as FulbackFC or Linebacker, set up the perfect installation for your plank-style sidings by providing a perfect ledge for each plank to stop up against for nailing. These installation guides ensure that every course of siding lines up exactly where it should for a perfect, straight appearance.

4.) Allows for wide profiles and darker colors

(for vinyl siding)

Some siding insulation products, such as FullbackV for vinyl, are contoured to fill the gap between the siding and the wall. The insulation can be laminated to the siding during manufacturing, combining the two products to make insulated vinyl siding. When in this form, the insulation provides additional structural strength to the siding panel. This allows for the siding to come in wider profiles and darker colors that aren’t always possible with traditional siding.

Insulated vinyl siding (left) provides wider profiles with straighter lines, unlike traditional vinyl (right) which can curve

When you’re at home, do you notice that you get headaches, have dry and itchy skin or nose and throat irritations? Or do you notice that you are sensitive to odors, feel nauseous or fatigued? Maybe you feel these symptoms when you’re in a particular room or even the whole house. If you do, these could be just a few signs that your home is has “sick building syndrome” or SBS, creating an unhealthy and even dangerous environment for you and your family.

When you’re at home, do you notice that you get headaches, have dry and itchy skin or nose and throat irritations? Or do you notice that you are sensitive to odors, feel nauseous or fatigued? Maybe you feel these symptoms when you’re in a particular room or even the whole house. If you do, these could be just a few signs that your home is has “sick building syndrome” or SBS, creating an unhealthy and even dangerous environment for you and your family.

According to the Environmental Protection Agency (EPA), the term SBS is “used to describe situations in which building occupants experience acute health?and comfort effects that?appear to be linked to time spent in a building, but?no specific illness or cause can be identified.”

The problem may be more prevalent than you think. A report from the World Health Organization stated that up to 30% of new and remodeled buildings worldwide could be linked to symptoms of sick building syndrome.

There are a number of potential causes of SBS, including:

1.) Inadequate ventilation

This is considered to be one of the biggest factors attributed to SBS. Inadequate ventilation can even occur if the systems in your home are not working properly, including heating and air conditioning systems. In addition, if you make improvements to your home such as adding certain types of insulation, you may be stifling the appropriate ventilation needed without even realizing it. Make sure you choose insulation products that won’t cause a problem in your home.

2.) Chemical Contaminants

Contaminants from both indoor and outdoor sources can include, but are not limited to, lead paint, pesticides, tobacco smoke, asbestos, water pollution and household chemical.s

3.) Biological contaminants

You may not realize that the average family of four generates 4-6 gallons of water vapor inside the home every day through activities such as cooking, showering, ironing and cleaning (think about how much steam comes from a hot shower). If this vapor doesn’t have a way to efficiently escape your home (such as through adequate ventilation), it can become trapped in the walls of your home and create some serious problems. Bacterias, mold, etc. can breed in stagnant water that accumulates in places like ducts, ceiling tiles, carpet and insulation.

4.) Pest infestations

Bird droppings and nesting insects can be an additional source of biological contaminants, not to mention the additional dangers that pests such as termites can pose. Take steps to protect your home from pests and other critters.

—————————————————————————————-

If you believe you or your family may be suffering due to your home’s SBS, contact a qualified building professional immediately to further inspect the potential problem.

When building or remodeling a home, be sure to take steps to prevent or reduce factors that can contribute to SBS. For instance, some products can improve ventilation, allow your home to breathe and release moisture, reduce air pollution and protect against pests, just to name a few.

For more information about sick building syndrome, visit the EPA’s website here.

Tax credits, or funds that are deducted from the total a taxpayer owes to the state, are being offered for energy-efficient upgrades that are made to homes. Some of these include credits towards wall insulation products, which can include siding insulation that is installed underneath new siding.

Many people hear about large federal tax credits when they are available, but they may not be aware that there are many other credits available through state and local governments as well as utility companies.

With so many different organizations offering credits for energy-efficient upgrades, it can be hard to determine all the tax credits that are available. We recommend visiting the Database of State Incentives for Renewables & Efficiency (DSIRE) at?www.dsireusa.org for information specific to your area. Dsireusa.org is a comprehensive source of information on state, federal, local and utility incentives for energy-efficient home upgrades.

Visit www.dsireusa.org for more information about tax credits available to you.